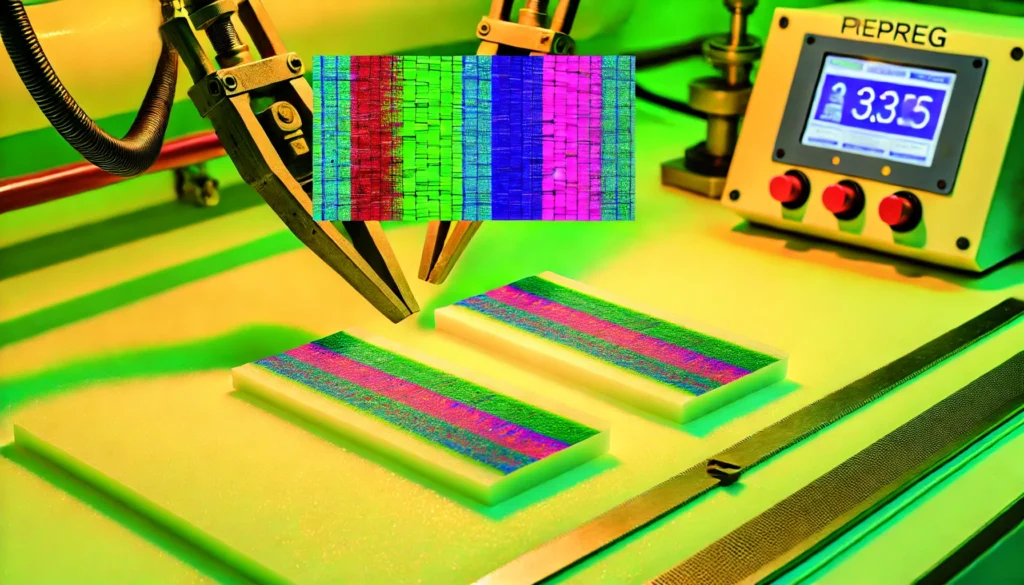

Applications of Prepreg — It is a very special material used in many industries (aerospace, automotive, construction etc.). When cured under heat, the resin and fibers together creates a product that is both durable and strong. Splicing — splices are a necessity when you’re using prepreg, since each piece of it is so small and weak that often two or more need to be combined in order to create the appropriate length. There are some important splicing-related requirements that you must follow to produce the best results.

What are the 10 general splicing requirements for prepreg that can determine you will succeed or fail.

What is Prepreg Splicing?

Prepreg splicing is also the method of joining together 2 or more pieces of prepreg material. This is very important as it will assure the strength and stability of the final part. When carried out correctly splicing allows the material to maintain its strength and functionality.

When it comes to splicing prepreg, a clean, good looking connection between the two pieces is critical. If the layers or splice are not sufficiently joined there will be a weak point in material where failure can cause issues in final product. Avoid this problematic incident by paying special attention to details and following correct procedures.

General Requirements for Splicing

Ensure Clean Surfaces

Prepreg surfaces must be clean before splicing. The more common issues are either bonding on the surface (infection) of dust, dirt or other debris. Appropriate solvent cleaning of the material ensures that a good bond will be achieved. This helps prepreg work appropriately in the resin.

Correct Overlap of Materials

A good overlap is crucial for just a strong splice. An overlap equal to the width of a prepeg material is proposed. The bond strength = prepreg itself so that there is no overkill.

Maintain Correct Temperature

TemperatureIt is the most significant parameter during splicing. A lower CTE means that the higher we can go with our glass transition temp, which is good when deploying a prepreg material into multiple layers of epoxy and copper foil (or anything else!) it needs to be able stand up at ~300° or 350°C indefinately! The resin in the prepreg is activated by heat allowing materials to bond together. Ensure the temperature in which you are working is consistent so as to not allow your resin curing too quickly or slowly.

Use Correct Pressure

It is equally important to splice with the proper pressure. The clamp pressure serves to hold the two pieces of prepreg together properly bonding. When the pressure exerted is too much or too little, it can lead to air bubbles or weak spots in there materials. Use the correct pressure for splicing according to the recommendations of your patch and strip manufacturer.

Avoid Excess Moisture

Prepreg materials will lose out of moisture, a bonding agent that is joined with them in order to bond together the subsequent layer [4]. Remember: The less moisture, the better for splicing. Prepreg should be stored in a dry environment and handled with cleanliness. The adsorption of moisture can result in poor product quality.

Align the Fibers Correctly

Fibers are used to give the prepreg strength It is essential that when splicing, you line up the fibres both in each piece of material. When fibers are misaligned, the material is weakened. Ensure that the fibres in both pieces are running in the same direction for maximum strength and performance.

Use the Right Tools

The cutting tools for splicing prepreg must be clean and sharp. This can cause damage to the prepreg and also reduce bond strength due to contaminants. Keep your cutting tools sharp and clean to make crisp cuts that bond well.

Work Quickly and Efficiently

Once the prepreg material is exposed to air or heat, it can begin curing. Again, splices are to be done correctly or nothing will work. Work thoroughly and quickly! If you take too long to splice the material, then by this time that part of the resin may have already started hardening fairly.

Adhere To Guidelines Provided By The Manufacturer

Different types of prepreg require a different type of processing in the splicing step. Read and follow the instructions that come with your type of prepreg. These are the actual directions that will provide you with accurate information on temperatures, pressures and handling.

Check the Splice For Defects

Inspecting Material After Splicing Check for air bubbles, crookedness, or hole. Fix any discovered issues, before proceeding to the next step. Good inspection and testing are what guarantee the strength of your final product.

How to Ensure Proper Splicing

Remember, always go by the basic rules and manufacturer guidelines to be accurate when you splice. But easier to control the environment, with proper tools and materials.

Clean the surface of the prepreg properly with clean piece if cloth before starting. This will help get rid of any dirt or dust that could interfere with the glue. After cleaning the surfaces, carefully aligning materials and applying appropriate pressure. It will allow for a nice smooth and consistent bond.

It is also crucial that they are properly temperature controlled. Prepreg resin is heat-reactive, thus temperature control also plays a significant role in creating good adhesion. By working in a dry environment, moisture is unable to interrupt the splicing process.

It is generally preferable to splice fast, but it must be done in a clean way. Work quickly, otherwise prepreg will begin to cure in the air. After the splicing is done, check it carefully for any defects or faults.

Prepreg Joining Tips

Keep Your Workspace Clean

Work in a clean environment as clear-room. The splicing can be interrupted by the dust or dirt. Having a clean workspace will allow the prepreg material to bond properly.

Check the Tools Regularly

Keep your cutting tools sharp and clean for prepreg splicing. If the tools are dull, they can tear at the material instead of cut it ultimately resulting in a very weak bond. Inspect your tools from the check list and have them in good conditions to work on splicing smoothly without any issues.

Monitoring Temperature and Humidity

Analysis of temperature and humidity also leads to the splicing process. An excessive quantity of heat can harden the resin too quickly, which weakens how perfectly it cures. Watch the WORKING CONDITION to make sure splicing is going smoothly.

Follow a Consistent Process

It means splicing every time, always the same way. Creating a sequence can prevent errors. Results in the final product are better if you stay consistent.

Inspect Regularly

Most of the issues can be addressed when one regularly inspects during, or even better after splice. This step has to be done in order for the final product is durable and strong.

Conclusion

The splicing with prepreg is the crucial process in industries that uses this materials. Knowing the correct steps is crucial because doing things in the right order will cause maximize its strength and performance, Splicing success is determined by cleaning surfaces, alignment, tools used and paying detail close to attention.

Meeting these 10 general prepreg splicing needs will allow you to achieve a strong and reliable bond that works in the final application. Remember to work in a safe environment, use operating tools and machinery with proper care, and follow instructions from the manufacturers for optimum results.